2023-07-26

Product Name/English Name:N,N'-Methylenediacrylamide

CAS:110-26-9

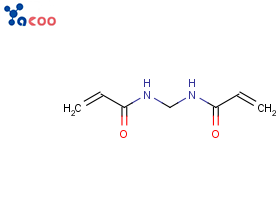

Molecular Formula:C7H10N2O2

Article No.:J0008

Structural Formula:

Product Introduction

N,N'-Methylenediacrylamide is a widely used crosslinking agent with stable quality, high purity, and good performance. It belongs to the thickening agent and adhesive of acrylamide. It is used in Textile manufacturing to produce thickening agent and adhesive, in oil exploitation to produce plugging agent. It is also widely used in various fields such as leather chemicals and printing.

Application of N,N'-Methylenediacrylamide

The function of lithium battery adhesive is to enhance the electronic contact between the electrode active material and the conductive agent, and better stabilize the structure of the electrode plate. Lithium battery adhesives are mainly divided into two categories: oil soluble adhesives and water-based adhesives. Oil soluble adhesives need to use organic solvents such as N-Methyl-2-pyrrolidone as dispersants, which are harmful to the environment and have poor adhesion to negative electrode materials. They are mostly used in positive electrodes of lithium batteries; Water is used as a dispersant for water-based adhesives, such as water-based acrylic resin, carboxymethyl starch, sodium alginate, styrene acrylic lotion, etc. The acrylic resin contains a large amount of carboxyl groups, which makes the molecular chains of water-based acrylic resin form hydrogen bonds, resulting in a certain degree of cross-linking. Therefore, the bonding performance is better than other water-based adhesives, but its brittleness and softness are poor, leading to the failure of the bonding force to meet higher requirements, This affects the continuous cycling stability of lithium batteries. Therefore, the CN116200147A patent develops a water-based adhesive and its preparation method, as well as its application in the negative electrode of lithium batteries, which improves the bonding force of water-based acrylic resin in the negative electrode of lithium batteries and endows them with good cycling stability.The preparation method of this water-based adhesive is as follows:

(1) Mix 0-5 parts by mass of surfactant, 150 -200 parts by mass of acrylic acid, 30-150 parts by mass of acrylonitrile, 5-200 parts by mass of acrylamide, and water. Heat the resulting mixed system to 60-90℃, add 1.1 to 2 parts by mass of initiator, and perform polymerization reaction for 2-8 hours to obtain linear polymer;

(2) Add a crosslinking agent to the linear polymer for crosslinking reaction at a temperature of 80-90℃ for 0.5-3h. After the crosslinking reaction is completed, lower the temperature and adjust the pH value of the reaction system to 6-7 to obtain a water-based adhesive;

The crosslinking agent can be one or more of N, N-methylenebisacrylamide, N-hydroxy Methacrylamide, methacrylic acid Acetoacetic acid ethylene glycol diester, Diethylenetriamine, triethylenetetramine, tetraethylenepentamine, polyethylene polyamine, nitrogen pyridine and diisocyanate.

Compared with existing technologies, this patent replaces some acrylic monomers with acrylonitrile and acrylamide to improve the strength and softness of the acrylic resin; Using acrylic acid, acrylonitrile, and acrylamide as monomers, linear polymers are first synthesized under the action of initiators, and then cross-linked to form a network like structure, improving the molecular weight and viscosity of water-based acrylic resin. Compared with linear acrylic resin, it has better adhesion, reduces the phenomenon of powder shedding of negative electrode materials during use, improves the cycling stability of batteries, and extends the service life of batteries.

References

CN116200147A A water-based adhesive and its preparation method, as well as its application in negative electrodes of lithium batteries.

Copyright © Suzhou Yacoo Science Co., Ltd. All Rights Reserved

Friendly Links :

online service