2023-09-19

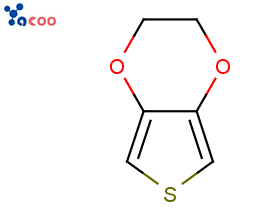

Product Name:2,3-dihydrothieno[3,4-b][1,4]dioxine

English abbreviation:EDOT

CAS:126213-50-1

Molecular Formula:C6H6O2S

Article No.: Y0038

Structural Formula:

Product Introduction

EDOT is mainly used for synthesizing conductive polymer PEDOT, as well as for synthesizing conjugated polymers and copolymers. It can also be used as a reducing agent in the synthesis of gold nanoparticles and as a raw material in palladium catalyzed single arylation and double arylation reactions. In addition, EDOT can also be used in composite material technology.

Application of EDOT

In recent years, with the gradual development of electronic components towards miniaturization and lightweight, the traditional Sn/Pb solder used in the electronic packaging industry has exposed its shortcomings. Conductive adhesive has a series of advantages such as simple coating process and low curing temperature. It has been used as a substitute for Sn/Pb in the microelectronic packaging industry, with silver based conductive adhesive being more widely used. At present, silver based conductive adhesives also have drawbacks in practical applications such as complex preparation, high resistance, and poor stability due to silver powder migration. Therefore, the CN103820066B patent provides a preparation method for silver based conductive adhesives. The specific preparation steps are:

1. Add γ- Mix cyclodextrin, silver nitrate, sodium polyacrylate, concentrated nitric acid, and distilled water in a mass ratio of 0.5: 20: 4: 1: 100, and stir to obtain solution A.

2. Mix ascorbic acid, 3,4-ethylenedioxythiophene, pyrrole-lysine, and distilled water in a mass ratio of 5:1:0.5:100, and stir to obtain solution B.

3. Heat solution A to 50 ℃, slowly add the same mass of solution B and stir, and finish dropping solution B within 30 minutes. After 1 hour of reaction, the insoluble substance was obtained by filtration, washed with a large amount of distilled water and ethanol, and dried to obtain the product silver based composite conductive particle C.

4. Mix epoxy resin E-44, curing agent triethylenetetramine, and silver based composite conductive particle C in a mass ratio of 1:0.7:5, and cure for 10 hours at 100 ℃ to obtain a volume resistivity of 2.5 × 10-5 Ω· cm conductive adhesive.

The resistivity of the conductive adhesive in this patent is (0.25-1.1) × 10-4 Ω· cm, low resistance, high conductivity.

References

CN103820066B A preparation method of silver based conductive adhesive.

Copyright © Suzhou Yacoo Science Co., Ltd. All Rights Reserved

Friendly Links :

online service