2023-10-23

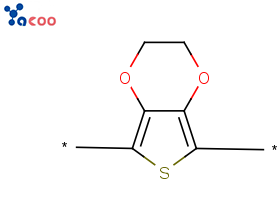

Product Name:Poly(3,4-ethylenedioxythiophene)

English abbreviation:PEDOT

CAS:126213-51-2

Molecular Formula:C6H6O2S

Article No.: J0230

Structural Formula:

Product Introduction

PEDOT is a polymer of EDOT. PEDOT has the characteristics of simple molecular structure, small energy gap, and high conductivity, and is widely used in the research of organic thin film solar cell materials, OLED materials, electrochromic materials, transparent electrode materials, and other fields.

Application of PEDOT

For electroluminescent devices, the balanced injection and effective transmission of electrons and holes are the basic conditions for obtaining efficient luminescence. However, currently known polymer materials are mostly p-type semiconductor materials, while n-type materials are rarely reported. Therefore, the injection potential barrier of electrons is large, and the transmission migration rate is low. To solve this problem, a main method is to use low functional metal calcium as the electrode to reduce the injection potential barrier. Although the calcium electrode is surrounded by metal aluminum for protection, it is still prone to react with oxygen and moisture in the air, causing device aging. Although packaging can slow down aging, it still cannot fundamentally solve aging. Another method is to evaporate a layer of inorganic salt and then protect it with metal aluminum. The performance indicators of such devices can also achieve the effect of calcium electrodes, but inorganic salts can also cause quenching centers, and evaporation also brings difficulty and cost to device preparation. To address this issue, CN1696171A patented the development of an alcohol soluble polyfluorene polymer material containing phosphate ester groups. The specific preparation process is:

Using pre cleaned ITO glass as the anode, a layer of conductive polymer polythiophene derivative (PEDOT) (50nm) was spun coated at a speed of 3000 rpm. The modified ITO was dried under atmospheric pressure at 110 ℃ for half an hour, and a chloroform solution with a concentration of 10mg/mL of poly [2,7-dibromo-9,9- (3 '- ethyl phosphate propyl) fluorene] was spun onto the surface of ITO at a speed of 1500 rpm. Subsequently, under vacuum conditions of 10-3Pa, 10nm of metal calcium and 100nm of metal aluminum were sequentially evaporated. The performance of single-layer electroluminescent devices is as follows: the starting voltage is 6.0V, the maximum brightness is 901cd/m2, the electroluminescent efficiency is 0.22cd/A at a brightness of 100cd/m2, and the color coordinates are (0.172, 0.167).

The preparation method of alcohol soluble polyfluorene materials containing phosphate ester groups as luminescent materials for electroluminescent devices is simple; The blue light device prepared from alcohol soluble polyfluorene polymer materials containing phosphate ester groups has high spectral stability and does not exhibit green peaks under high voltage. The device can also achieve full color display.

References

CN1696171A Alcohol soluble polyfluorene materials containing phosphate ester groups as luminescent materials.

Copyright © Suzhou Yacoo Science Co., Ltd. All Rights Reserved

Friendly Links :

online service