2024-01-08

Product Name:Parylene N

CAS:1633-22-3

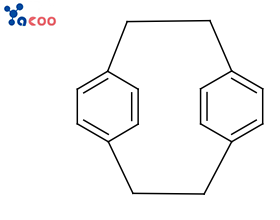

Molecular Formula: C16H16

Article No.:D0015

Structural Formula:

Product Introduction

Parylene N is mainly used as a high-purity passivation layer and dielectric layer in microelectronics and semiconductors. It can also be used as passivation, protection, lubrication and other coatings in microelectronics; In addition, it can also be used as isolation, solidification, and reinforcement materials in biomedical anti-corrosion and cultural relic protection.

Application of Parylene N

A power module is a module composed of power electronic components that are encapsulated according to a certain functional combination. At present, the power module is usually filled with silicone gel or epoxy resin curing adhesive, but silicone gel can only prevent the invasion of liquid water, while gaseous water can still enter the power module and cause corrosion to internal electronic components; Although epoxy resin cured adhesive has good waterproof performance, its flowability is poor. Therefore, the sealing layer formed by it is prone to delamination and voids. Water vapor will enter the power module through the interlayer gaps and voids, corroding internal electronic components and reducing the reliability of the power module. Moreover, the power module will generate heat during operation. If the external humidity is high or there is water vapor inside, a high-temperature and high humidity environment will be formed. Under these conditions, the voltage resistance performance of the power module will decrease, making it more prone to corrosion of internal electronic components and circuits, resulting in leakage and internal short circuits of the power module. Therefore, improving the reliability of power modules under high temperature and humidity conditions has become an urgent technical problem to be solved.Therefore, the CN117199009A patent provides a power module. The power module mainly includes the power module body, protective film, housing, and sealing layer. The components of this protective film include high temperature resistant, waterproof and moisture-proof Parylene N. The specific preparation method for protective film is as follows:

Use adhesive tape to protect the welding area on the back and front of the qualified power module substrate. Then, place the power module body into a chemical vapor deposition equipment and use the precursor of Parylene N as the raw material for Parylene N deposition. The chemical vapor deposition time is 60 minutes, the temperature is 25℃, and a thickness of 5μm is formed Parylene Nfilm.

The Parylene N material is covered on the surface of the power module body, which acts as a barrier against water vapor and hardly decomposes under high temperature and humidity conditions. Therefore, under these conditions, the protective film can still provide good protection and effectively alleviate the corrosion of electronic components and circuits inside the power module.

References

CN117199009A Power modules and their preparation methods, semiconductor devices.

Copyright © Suzhou Yacoo Science Co., Ltd. All Rights Reserved

Friendly Links :

online service