2023-09-08

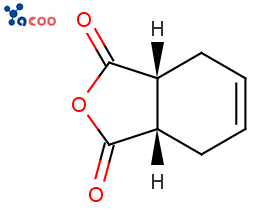

Product Name/English Name:cis-1,2,3,6-Tetrahydrophthalic anhydride

English abbreviation:THPA

CAS:935-79-5

Molecular Formula: C8H8O3

Article No.:S1112

Structural Formula:

Product Introduction

THPA is an important chemical product, mainly used as a curing agent for epoxy resins, a modifier for unsaturated polyester resins and alkyd resins, and an important intermediate in the synthesis of pesticides and pharmaceuticals. In addition, THPA can also be applied to cable protection pipe.

Application of THPA

The power protective casing is divided into two types: excavation type and non excavation type. The existing power sheath pipes have the characteristics of high temperature resistance and external pressure resistance, and are suitable for high-voltage transmission lines and cable duct pipes above 10kV. At the same time, the power casing has excellent electrical insulation, high thermal deformation temperature, and low temperature impact performance, which can be widely used in municipal, telecommunications, power, gas, tap water, heat and other pipeline engineering.

However, with the further development of power and telecommunications pipeline engineering, power sheath pipes need to be used at greater depths and higher transmission voltages. Therefore, power sheath pipes used in power and telecommunications pipeline engineering need to have higher impact resistance and heat resistance to meet the requirements of special environments. In this context, the CN116462911A patent has developed a high impact and heat resistant power sheath pipe and its production process. The power sheath pipe includes 90-110 parts of polypropylene, 15-20 parts of wollastonite powder, 0.5-1 parts of coupling agent, 40-50 parts of compatibilizer, and 0.3-0.4 parts of nucleating agent.

The nucleating agent is prepared by the following steps:

1. Add cis-1,2,3,6-tetrahydrophthalic anhydride to tetrahydrofuran, stir at room temperature until completely dissolved, then slowly add a tetrahydrofuran solution of p-phenylenediamine. After the addition is completed, react at room temperature for 6 hours, filter, and obtain intermediate 1;

2. Dissolve intermediate 1 in deionized water, raise the temperature to 70℃for complete dissolution, then slowly add a saturated solution of sodium bicarbonate to a pH of 7, and then add lanthanum nitrate while stirring for 8 hours. After the reaction is completed, filter and wash the filter residue with water three times to obtain a nucleating agent.

The self-made nucleating agent in this patent contains highly symmetric bisamide and carboxyl groups, which have good thermal stability. Combined with the metal lanthanum element, it effectively induces the production of a large amount of polypropylene βCrystal, Obtained good mechanical properties, allowing modified wollastonite to react with compatibilizers β Crystalline polypropylene is firmly bonded, achieving better impact resistance.

References

CN116462911A A High Impact and Heat Resistant Power Sheath Pipe and Its Production Process.

Copyright © Suzhou Yacoo Science Co., Ltd. All Rights Reserved

Friendly Links :

online service