2017-07-14

Parylene is a generic term for a series of polymers prepared with vacuum vapor deposition process by the United States Union Carbide Co. in the sixties, which can be applied to the various shape of the surface. It has the functions of waterproof, moistureproof, mildewproof, anti-corrosion, anti-salt spray. Depending on the molecular structure, Parylene can be classified into N, C, D, F, HT and other types. What is the differences between these types?

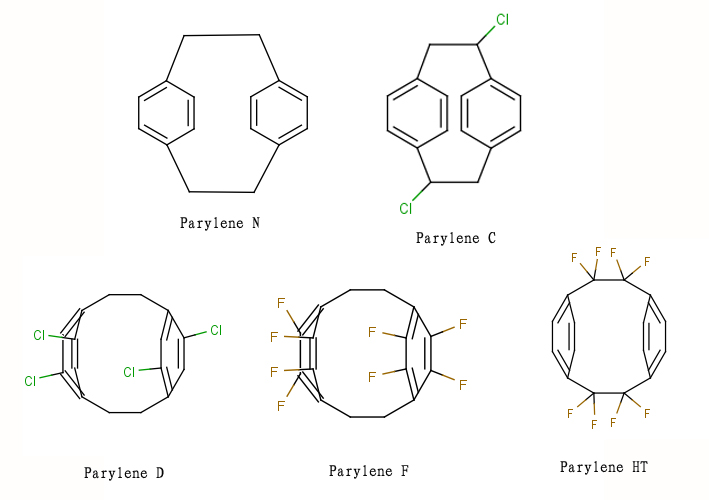

Molecular Structure

Parylene N, poly-p-xylylene, substituting a hydrogen atom in the dimethyl group with a chlorine atom to give Parylene C; replacing the two aromatic hydrocarbon hydrogen atoms with chlorine atoms to give Parylene D; Parylene F can be obtained when the four hydrogen atoms on the benzene ring are replaced by fluorine; and the H atoms in the dimethyl are replaced by F atoms, HT-type Parylene can be obtained.

Performance and Application

Parylene N is a good dielectric material with low dielectric loss, high dielectric strength, and dielectric constant that does not vary with frequency. In all kinds of Parylehe, Parylehe N has the strongest penetrating ability, as well as good self-lubricating properties. Parylene N meets the biological test requirements of ISO-10993.

Parylene C combines good electrical properties and physical properties together, and has a very low transmittance for water molecules and corrosive gas. It can provide a true isolation without pinhole, it is the preferred material for important circuit boards. Parylene C meets the US military standard MIL-46058C, and is in line with the biological test requirements of ISO-10993.

Parylene D is similar in nature to Parylene C, but with higher heat resistance. It still has excellent dielectric properties and physical and mechanical properties at high temperature.

Parylene F, the film has a high dielectric strength and low dielectric constant, good thermal stability, and anti-UV ability. The film is continuous, dense, without pinholes, and can be used as a protective film for various electronic device with complex shapes.

Parylene HT has a lower dielectric constant, good stability and waterproof, mildewproof, anti-salt spray performance. The temperature resistance is up to 450°C for a short time and 350°C for long-term, and it has a strong anti-ultraviolet ability. It is protection material that is more suitable for high-frequency microwave device. Parylene HT is also in line with the biological test requirements of ISO-10993.

In addition to the above excellent protective properties, Parylene also has good biocompatibility, good biological stability, excellent self-lubricating, and good physical and mechanical properties. Over the years, it already has a wide range of applications in aerospace, microelectronics, semiconductors, sensors, magnetic materials, medical equipment, cultural relics protection and other fields, and has slowly penetrated into people's daily lives.

Edited by Suzhou Yacoo Science Co., Ltd.

Copyright © Suzhou Yacoo Science Co., Ltd. All Rights Reserved

Friendly Links :

online service