As we all know, protective polymer materials Parylene are a kind of powerful material with the function of waterproof,mouldproof and salt spray proofing. But have you ever thought about that why parylene has not monopolized the whole coating industry?

What are the advantages of Parylene?

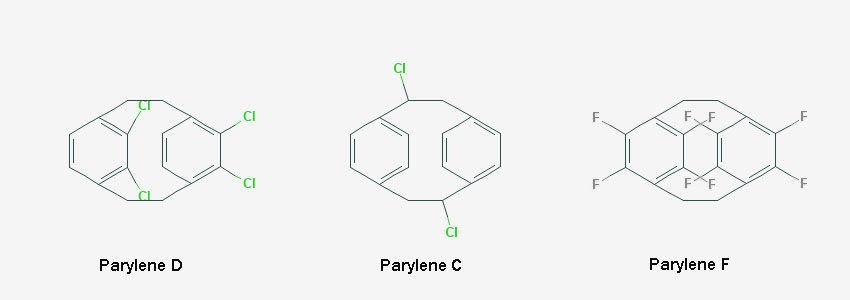

According to the different molecular structure, Parylene falls into several kinds: Parylene D, Parylene C and Parylene F, etc. Parylene coatings have advantages that others can not match: it can be applied to various shapes of the surface, including the sharp edges, cracks and inner surface; It can provides a true pinhole-free film; It has many characteristics including stability, hydrophobicity, biocompatibility, chemical immiscibility, low permeability, high insulation, and so on.

Parylene has been widely applied to various fields:

But why parylene has not monopolized the whole coating industry?

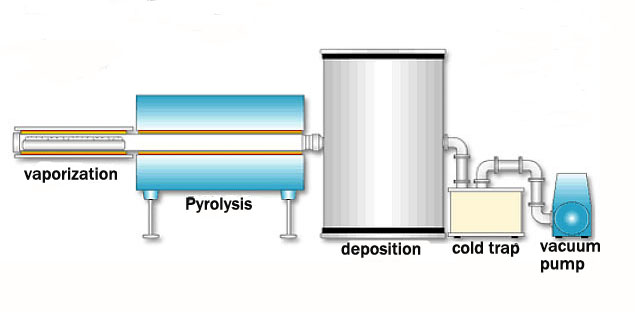

Parylene coatings are prepared by vacuum vapor deposition process. Look at the preparation process of optoelectronic material Parylene F: The preparation of the film is carried out on a dedicated vacuum coating apparatus consisting of sublimation furnace, cracking furnace, deposition chamber, cold trap and vacuum system. Parylene F dimer (Octafluoro[2.2]paracyclo-phane) sublimates in sublimation furnace, cracks into active monomer free radicals in cracking furnace, and deposits to be film in deposition chamber.

Due to technical limitations and high demands of the experiment, when it is not necessary, people tend to choose a relatively simple method; on the other hand, due to the high cost, Parylene generally used in high-value products. So Parylene has obtained the high-precision products market, but not be widely applied to the common coating market.

Perhaps in the future, with the rapid development of science and technology, the process will be simplified and the cost will be reduced, this excellent coating material can also access to the regular product market.

Copyright © Suzhou Yacoo Science Co., Ltd. All Rights Reserved

Friendly Links :

online service