2024-04-10

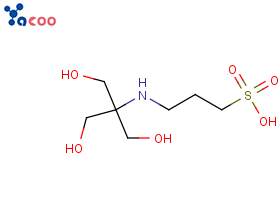

Product Name:TAPS

CAS:29915-38-6

Molecular Formula:C7H17NO6S

Article No.: S0007

Structural Formula:

Product Introduction

Trihydroxymethylaminopropanesulfonic acid is a zwitterionic buffering agent that can be used as an important pH stabilizer in biochemical experimental. It is generally mixed with weak acids and their conjugated bases to obtain an appropriate pH value.

Application of TAPS

The membrane separation process is carried out at room temperature, without phase change and secondary pollution. It is an efficient and energy-saving separation and purification technology, widely used in the separation and refining of chemical processes, environmental protection fields such as wastewater purification treatment, useful substance recovery in water, zero discharge system for industrial wastewater, and activated sludge membrane wastewater treatment. Porous membranes are commonly used as the base membrane for composite membranes such as reverse osmosis membranes, nanofiltration membranes, gas separation membranes, and pervaporation membranes. The existing porous membrane materials mainly include polyvinylidene fluoride, polysulfone, polyethersulfone, polyethylene, polypropylene, etc. The preparation of polyvinylidene fluoride (PVDF) film using solution phase transfer method is a commonly used method for film preparation. By adjusting the proportion of PVDF resin, solvent, and pore forming agent in the PVDF film forming mixture, stirring at 50-90 ℃ to prepare a casting solution, and then solidifying the casting solution in a coagulation bath to obtain a porous PVDF film. However, the polyvinylidene fluoride porous membrane prepared by this preparation method still has problems such as low hydrophilicity and low water production flux. Therefore, CN114699934A patent aims to improve the performance of polyvinylidene fluoride porous membranes and polyvinyl chloride based membranes by preparing polyvinylidene fluoride/polyvinyl chloride blended porous membranes through the method of blending. The specific preparation method is as follows:

Mix 67wt% of dimethyl acetamide (industrial grade pure), 18wt% of polyvinylidene fluoride resin (Solef 6010), 3wt% of polyvinyl chloride resin (degree of polymerization 1000), 10wt% of polyethylene glycol (molecular weight 6000 Daltons), and 2wt% of trimethylolmethylaminopropanesulfonic acid, stir and dissolve uniformly at 60 ℃, and defoaming. The conventional solution phase transfer method is used for spinning, with a coagulation bath of water and a spinning core solution of 60wt% dimethylacetamide aqueous solution. The spinning traction speed is 50m/min.

Obtained a polyvinylidene fluoride hollow fiber blended porous membrane under external pressure, with an inner diameter of 0.60mm, a wall thickness of 0.20mm, a rupture pressure of 0.42MPa, and an external flattening pressure of 0.35MPa. The contact angle on the outer surface of the hollow fiber membrane is 58°. The initial permeate flux of pure water is 870L/㎡ · h @ 0.1MPa at 20 ℃, and the membrane separation pore size is 0.20 μ M.

This patent uses a polyvinylidene fluoride/polyvinyl chloride blend porous membrane to first react with a polyamine aqueous solution to form an intermediate layer of the composite membrane. Then, following the conventional interface polymerization reaction process to prepare the composite membrane, the surface of the intermediate layer of the composite membrane is coated with the aqueous solution of the conventional interface polymerization reaction, and then comes into contact with the oil phase solution of the conventional interface polymerization reaction to prepare a high-throughput and high selectivity reverse osmosis membrane and nanofiltration membrane.

References

CN114699934A A Separation membrane materials, preparation methods, and applicationsd.

Copyright © Suzhou Yacoo Science Co., Ltd. All Rights Reserved

Friendly Links :

online service