2017-09-05

Poly(3,4-ethylenedioxythiophene) (PEDOT) are widely used in the field of antistatic coatings, optoelectronic devices, capacitors, electromagnetic shielding, sensors, metal corrosion, etc. due to its high conductivity, low energy gap, excellent film transparency and environmental stability. But its insoluble problem limits its application. In addition to the addition of polystyrene sulfonic acid (PSS), many researchers have begun to explore other methods, such as the preparation of core-shell dispersions of PEDOT and other substances. In this paper, the preparation of several main PEDOT core-shell dispersions will be summarized.

PEDOT-polystyrene (PS) core-shell dispersion

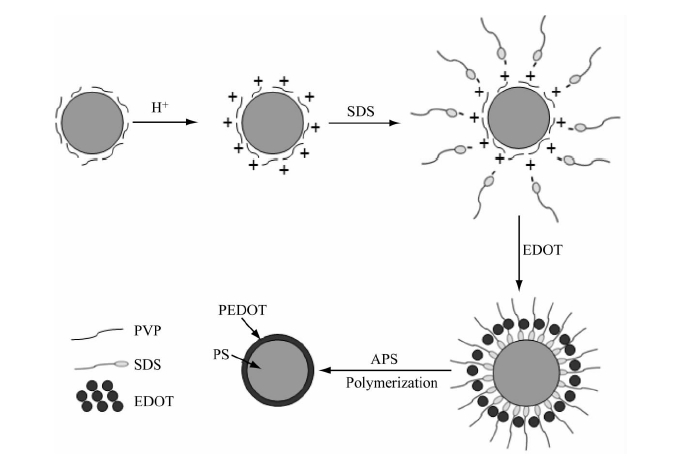

(APS) as the initiator, and the micro-scale core-shell PS-PEDOT composite was prepared by oxidative polymerization by Han Guozhi et al. [1]. Under the conditions of the aqueous phase, in order to promote the polymerization of EDOT on the surface of PS microspheres, the surface of the microspheres must be modified. The researchers dispersed PS microspheres in distilled water which modified by PVP as the stabilizer, and then adjust the pH of the solution to acid to promote the PS microspheres surface PVP protonation, which showed positive electricity, then add the surfactant SDS. Under the electrostatic interaction, SDS forms a layer of loose organic layer on the surface of microspheres, which is beneficial to the enrichment of EDOT monomer on the surface of PS microspheres. With the increase of the amount of monomer EDOT, the amount of conductive polymer on the surface of the microspheres also increases. This kind of conductive microspheres have potential application prospects in photonic crystal, pressure sensitive electronic devices and drug delivery.

PEDOT-Si core-shell dispersion

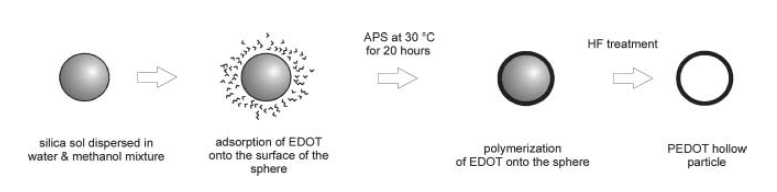

In the synthesis process, EDOT monomer was first dissolved in a diluted colloidal silica solution with a diameter of ca. 130nm. Because the EDOT monomer is only slightly soluble in water, the solubility of EDOT in the dispersion medium was controlled by mixing methanol with deionized water and/or by using p-toluenesulfonic acid (p-TSA). The EDOT adsorbs to the surface of the colloidal silica, where polymerization is initiated by the addition of the oxidant ammonium persulfate (APS) to the stirred solution. After 20h of polymerization at 30 uC, the PEDOT shells are formed around the silica spheres. Repetitive centrifugation and re-dispersion is performed after the polymerization to remove possible side reactants as well as unreacted chemicals. By further processing, the silicon core can also be removed to obtain a PEDOT hollow sphere that can be used to prepare photonic crystals or catalysts.

PEDOT-polyurethane (PU) core-shell dispersion

By recombination of PEDOT with monodisperse microspheres to prepare a dispersion with core-shell structure, it can solve the problem of poor solubility and difficult processing in PEDOT, and improve its application performance, which makes PEDOT gain wider application in photonic crystal, catalyst, antistatic coating and drug delivery.

References

[3] Sun Dongcheng, Zhang Sha. Preparation and Application of PEDOT Core-shell Dispersion Based on Polyurethane. New Materials for Chemical Industry, 2010, 38, 160-172.

Copyright © Suzhou Yacoo Science Co., Ltd. All Rights Reserved

Friendly Links :

online service